PVC|PET Clear Window Paper Box

As a leading China packaging box supplier, Shanghai DE Printed Box manufactures the custom clear window paper boxes, clear window corrugated boxes and clear window rigid paper boxes and gift boxes.

Clear PET, PVC Window

For a paper printed box with the clear PVC or PET window, the consumers can see the inner product clearly through the transparent plastic window. This gives the consumer a better understanding of the products. Children buy a toy just because what he sees through the clear window of the paper box. The plastic window is particularly widely used in the toys packaging boxes, barkery food packaging box, cosmetic paper boxes. It has the ripple effect on the marketing.

Clear Window Materials

The clear transparent plastic window is mostly made of the PVC and PET. And the latter is very eco-friendly because it is totally recyclable. The paper food boxes usually choose the PET plastic material to make the clear window of the paper box.

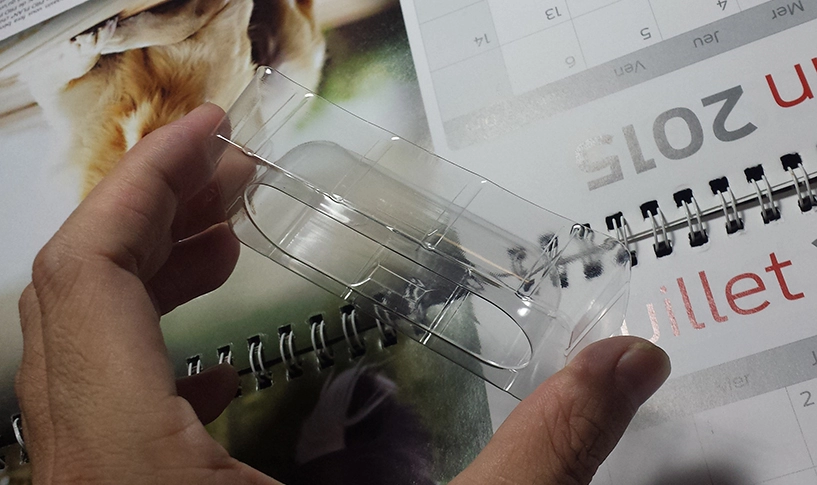

After the creasing and diecut of the PVC|PET materials, there is usually 2 ways to make the window box. One solution is that we glue the PET|PVC to the inner surface of the corrugated printed box. Another solution is that the PET|PVC is folded to make a sleeve. Then the sleeves can slide in to the paper box.

And the thickness of the PET/PVC is varied from 0.15mm to 0.30mm. For the paper printed box with the PET sleeves, the 0.25mm, 0.30mm is widely applied.

The clear window on the paper box can be any shape. They are square window box, rectangular window box, heart shape window box and other custom shapes. Besides the common clear window boxes which have the plastic window on the front panel, the clear plastic window can be folded and glued to the side panels of the paper box. It is called a corner window box, or paper box with the corner window.

Also, you can have a PET or PVC blister insert to put inside the printed paper box to hold the product.

Paper Material for the Window Box

In DE Printed Box, the clear window paper box can be divided into 3 categories.

- Clear window corrugated printed box

- Clear window paper printed box

- Clear window rigid paper box

For the toy packaging box, the Corrugated Board is usually used because of the good cushioning property and strength. It can protects the toys inside very good. While for the bakery food packaging, the good grade material is used, like kraft paperboard, SBS paperboard. Beside these 2 paper materials, sometimes the white lined chipboard which has the grey back is used to reduce the costs.

The custom folding paper box, E, F flute corrugated box, cosmetic|toy|retail packaging paper box often have the clear plastic window to display the products inside.

Printing and Finish for the Window Box

The paper|corrugated printed window box usually go with the offset printing, which renders a very high quality graphic surface. As for the finish, a glossy and matte effect can be chosen, either for laminating or varnishing. Sometimes, our clients choose the spot UV for their logo to have an very glossy and embossing feel, very appealing and luxury.

Clear Window Paper Box Styles

According the paper box structure and styles, the clear window paper box can be divided into the categories below.

Glossy Black Paper Box With Clear Plastic Window

Clear Window Cosmetic Paper Box

Straight tuck end box style; CMYK+PMS litho offset printing; 0.3mm thickness PVC window; Glossy Black color.

Paper Food Box With the Corner Window

Clear Window Paper Box for Food

The paper box above is a food paper box with the clear window.

The plastic sheets can be die-cut to be glued to the front panel and side panels of the paper box to have a corner window paper box. They are widely used for the bakery food packaging box and toy paper box. Then the consumers can have a better view of the bakery food and toy inside through the clear window.

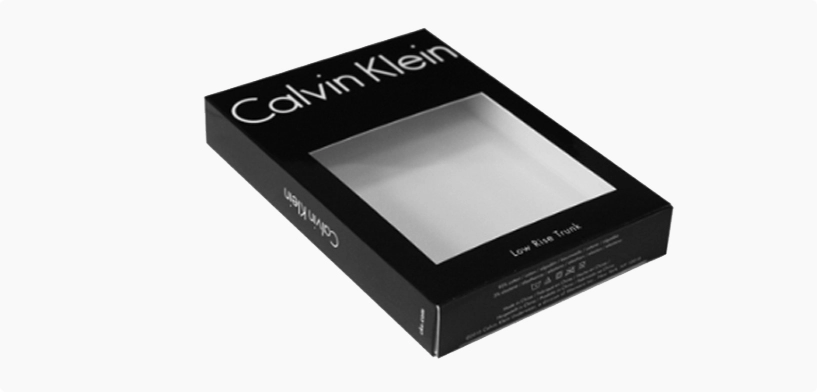

Underwear Paper Box With Clear PVC Window

Clear Window Paper Box of STE Box Style

The black paper box above is a underwear packaging box with the clear plastic window.

The main usage of the clear window box is the retail products packaging, such as underwear, earphone, caps, toys, bakery food, lip balm and others.

Corrugated Printed Box With Clear PVC Window

Clear Window Corrugated Printed Box

This is a corrugated window box made of the E flute corrugates. The box is used for the toy packaging. It has the plastic handle for the easy carrying. Also on the front panel, children can see through the clear window to have a close look of the toy inside.

Besides the SBS paperboard, the E flute Corrugated Board are often used to make the window box when a stronger packaging box is necessary. Also the rigid gift box can have a clear window too.

Lip Balm Paper Box With Clear Window

Clear Window Cosmetic Paper Box

The lip balm paper box above is a straight tuck end paper box with the tab on the top. On the front panel, the 0.2mm thick PET sheet is used to create the clear window.

The clear window cosmetic paper box is one of our featured products by using the luxury creative papers.

Blister Insert Inside the Paper Printed Box

The PET blister inside the lip balm paper box made of the 0.35mm PET sheets.

Corner Window Box for the Cap Packaging

Paper Printed Box With Corner PVC Window

This is a cap presentation and display box with the clear pvc window on 3 panels of the box. The box has the straight tuck end box style and black UV varnishing, very eye-popping.